Executive Introduction

The transformation bearing down on global labor markets is not a distant forecast. It is unfolding now. According to the World Economic Forum's Future of Jobs Report 2025, automation and artificial intelligence will displace an estimated 92 million jobs worldwide while simultaneously creating 170 million new roles, resulting in a net gain of 78 million positions by 2030. For university leaders, this presents both an urgent challenge and a defining opportunity.

The scale of disruption demands institutional response. The same WEF report found that 63% of employers cite skills gaps as their primary barrier to business transformation. Universities that equip students with the skills to bridge this gap will produce the innovators, engineers, and leaders of tomorrow. Those that fail to adapt will graduate students into a workforce that has moved on without them.

Robotics education stands at the center of this transformation. Far from being a niche technical discipline, robotics has emerged as a foundational pillar of institutional strategy for producing adaptable, employable graduates. The global educational robotics market reflects this recognition: Grand View Research estimates growth from approximately $1.4 billion in 2024 to $5.8 billion by 2030, a compound annual growth rate exceeding 28%. Universities worldwide are investing heavily, and for good reason.

This article examines why robotics education has become essential for building future-ready students, how it benefits learners across multiple dimensions, and what strategic steps university leadership should take to integrate robotics into their institutional vision.

Key Statistics at a Glance

Metric | Figure | Source |

|---|---|---|

Jobs displaced by 2030 | 92 million | WEF Future of Jobs Report 2025 |

New jobs created by 2030 | 170 million | WEF Future of Jobs Report 2025 |

Employers citing skills gaps as top barrier | 63% | WEF Future of Jobs Report 2025 |

Skills expected to change by 2030 | 39% | WEF Future of Jobs Report 2025 |

Educational robotics market (2024) | $1.4 billion | Grand View Research |

Educational robotics market (2030 projected) | $5.8 billion | Grand View Research |

VEX Robotics participants globally | 1.1 million students | REC Foundation |

VEX participants reporting increased STEM interest | 95% | REC Foundation |

Robotics and the Evolving Future Workforce

The Automation Landscape

Robotics has moved well beyond the factory floor. Today, robotic systems permeate nearly every major sector of the economy.

In healthcare, surgical robots assist with precision procedures while rehabilitation robots help patients recover mobility. In manufacturing, the automotive industry maintains one of the highest robot densities of any sector, with robots performing welding, painting, and assembly operations at scale. The International Federation of Robotics reported an all-time high of over 517,000 new industrial robot installations globally in 2022, representing 31% growth over the prior year.

Agriculture employs autonomous systems for planting, harvesting, and monitoring crops. Logistics companies deploy fleets of warehouse robots to manage inventory and fulfill orders. Defense and aerospace rely on robotics for everything from reconnaissance to space exploration.

What distinguishes the current moment is the convergence of robotics with artificial intelligence. Nvidia CEO Jensen Huang describes this as the era of "physical AI," where robotic systems use real-time data from sensors and cameras to perform complex tasks requiring dynamic decision-making. Unlike earlier generations of industrial robots that followed pre-programmed sequences, today's systems perceive their environments, adapt to changing conditions, and collaborate with human workers.

New Roles and Skill Demands

The implications extend to the types of roles available in the labor market. While routine coding, data entry, and basic IT support face increasing automation, new categories of employment are emerging.

Organizations now seek AI system architects who design intelligent systems, human-robot collaboration specialists who optimize the interface between people and machines, ethics and governance professionals who ensure responsible deployment, and physical AI engineers who work at the intersection of software and mechanical systems.

The WEF report identifies AI and big data as the fastest-growing skill areas through 2030, followed by networks and cybersecurity, and technology literacy. These roles did not exist a generation ago, and they require educational preparation that traditional curricula were not designed to provide.

Implications for Higher Education

For universities, the message is clear: the purpose of education must shift from training students to perform tasks toward training students to design, manage, and collaborate with automated systems. This is not merely an adjustment to course catalogs. It represents a fundamental reorientation of institutional mission.

Industry has already signaled its priorities through action. Companies like Boston Dynamics, ABB Robotics, and Tesla have established partnerships with universities specifically to build talent pipelines.

ABB's introduction of the IRB 1090 educational robot, authenticated by STEM.org, explicitly targets the goal of upskilling students for future workforce needs. Boston Dynamics promotes its Spot robot as a platform to help students understand applications ranging from routine operations monitoring to hazardous environment response.

Universities that ignore this shift risk producing graduates whose skills are already obsolete upon commencement. Those that embrace it position themselves as essential bridges between technological disruption and economic opportunity.

How Robotics Programs Benefit Students

Technical Skill Development

Robotics education is inherently interdisciplinary. Unlike traditional engineering programs that specialize in a single domain, robotics requires students to integrate knowledge from mechanical engineering, electrical engineering, computer science, and artificial intelligence. This integration mirrors the reality of modern engineering practice.

Students in robotics programs develop hands-on proficiency with industry-standard tools and technologies. They learn programmable logic controller (PLC) programming, mechatronics, sensor integration, control systems theory, and robotics software platforms. They work with actuators, motors, and mechanical assemblies. They write code that translates into physical action.

Leading institutions have recognized that classroom instruction alone cannot produce workforce-ready graduates. Programs at Carnegie Mellon, Northwestern, Bowling Green State, and Santa Clara University feature laboratory environments that simulate industrial conditions.

Bowling Green State's eFactory provides a 1,558-square-foot open classroom where students engage in competency-based experiential learning using current-generation equipment. Graduates from such programs can transition immediately to professional settings because they have already encountered the tools and challenges they will face on the job.

Higher-Order Cognitive Skills

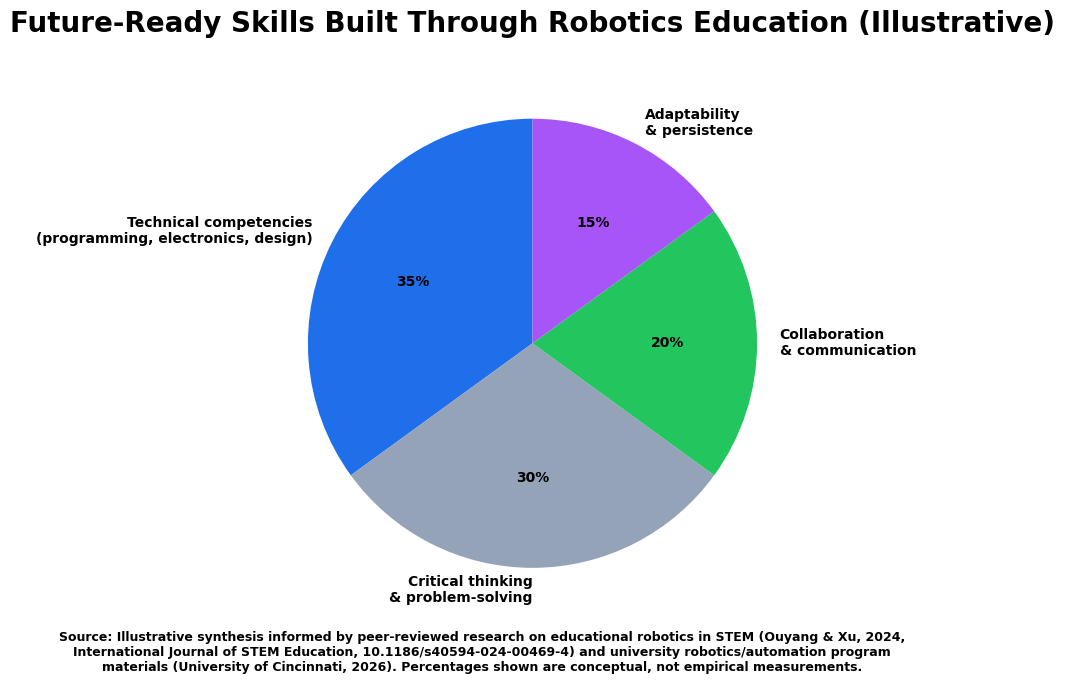

The benefits of robotics education extend well beyond technical proficiency. The process of designing, building, and programming robots cultivates cognitive skills that transfer across disciplines and careers.

Problem-solving under constraints is central to robotics work. Students must define objectives, allocate limited resources, test prototypes, analyze failures, and iterate toward solutions. This cycle builds systematic thinking and resilience.

Computational thinking develops naturally through robotics coursework. Students must decompose problems, identify patterns, abstract general principles from specific cases, and design step-by-step procedures. These skills apply far beyond robotics.

A 2025 bibliometric analysis published in Humanities and Social Sciences Communications (Nature) examined over 1,100 peer-reviewed publications on robotics in education from 2015 to 2024. The research found that robotics education significantly improves student engagement and fosters computational thinking across age groups and educational levels.

Collaborative and Professional Competencies

Modern robotics projects are team endeavors. Students work in groups to design systems, divide responsibilities, coordinate efforts, and integrate components built by different team members. This structure mirrors professional engineering teams.

Competitive robotics programs amplify these benefits. The Robotics Education and Competition (REC) Foundation supports programs reaching over 1.1 million students across 70 countries. Competitions such as FIRST Robotics and VEX Challenges require teams to manage timelines, allocate roles, communicate effectively, and perform under pressure.

The data on outcomes is compelling: 95% of VEX competition participants report increased interest in STEM subject areas and pursuing STEM-related careers, according to the REC Foundation. Participants develop leadership capabilities, project management skills, and the ability to present technical work to diverse audiences.

Coding, Robotics, and Workforce Automation Readiness

Beyond Code: Systems Thinking

Learning to code in a robotics context differs fundamentally from learning to code in isolation. When students write software for robotic systems, they must think in terms of complete systems rather than isolated scripts.

They consider how code interacts with sensors, how commands translate to motor movements, how feedback loops maintain stability, and how the physical environment constrains algorithmic possibilities.

This systems perspective equips graduates for the realities of an automated workforce. Professionals working with the Internet of Things, autonomous vehicles, smart manufacturing, and related domains must understand the full stack from software to hardware to physical implementation. Robotics education provides this understanding in ways that pure computer science curricula often do not.

Building Human-AI Collaboration Skills

The future workforce will not feature humans competing against robots. It will feature humans working alongside robots, with each contributing distinct capabilities. Robotics education trains students for this collaborative paradigm.

Students learn to design interfaces that optimize human-robot collaboration, understanding where human judgment adds value and where automation excels. They study "co-bot" systems, collaborative robots designed to work safely alongside human operators, which represent one of the fastest-growing segments of industrial robotics.

Ethical considerations increasingly factor into this preparation. As AI systems make more autonomous decisions, the engineers who design them bear responsibility for the outcomes. Robotics curricula now incorporate discussions of algorithmic bias, safety protocols, accountability frameworks, and the societal implications of automation.

Adaptability as a Core Outcome

Perhaps the most durable outcome of robotics education is adaptability itself. Robotics curricula must evolve rapidly to keep pace with technological change. Students trained in this environment develop comfort with continuous learning as a professional norm.

The WEF reports that 39% of existing skill sets will be transformed or become outdated between 2025 and 2030. Exposure to emerging technologies, including machine learning integration, computer vision, and autonomous navigation, ensures graduates remain relevant as industries transform.

More importantly, students develop the metacognitive skills to learn new technologies independently. In a labor market where the specific technologies in use will change multiple times over a career, this adaptability may be the most valuable skill of all.

Technology's Role in Shaping Future-Ready Education

Pedagogical Transformation

Robotics education exemplifies broader shifts in pedagogy that research has validated over recent decades. Experiential, project-based learning produces superior outcomes compared to passive instruction.

Students retain more information, develop deeper understanding, and transfer skills more readily to novel contexts when they learn through active engagement. Technology enables these pedagogical advances at scale.

Simulation environments allow students to test robotics concepts virtually before physical implementation, reducing costs and accelerating iteration cycles. Adaptive learning platforms provide personalized feedback, enabling students to progress at their own pace. Online resources extend learning beyond classroom hours.

These tools do not replace faculty expertise. Rather, they amplify it. Instructors can focus their limited contact time on high-value activities: mentoring students through complex projects, facilitating discussions of ethical implications, and providing the nuanced feedback that automated systems cannot replicate.

Institutional Positioning and Competitive Advantage

Universities that integrate robotics position themselves as innovation leaders. This positioning attracts research funding from government agencies prioritizing automation and AI. It draws corporate partnerships from companies seeking talent pipelines and collaborative research opportunities. It recruits high-caliber students who recognize that their choice of institution will shape their career prospects.

Strategic alignment with national priorities strengthens this positioning. The U.S. National Robotics Strategy, outlined by the Association for Advancing Automation, calls for coordinated investment in robotics education and workforce development. Similar initiatives exist in Europe, Asia, and elsewhere.

Beyond competitive advantage, technology integration serves equity goals. Strategic deployment of educational technology can ensure that graduates from all backgrounds are equipped for the digital economy.

Faculty Development Imperative

Sustainable robotics programs require investment in faculty capabilities. Many current faculty members completed their education before robotics reached its present prominence.

Professional development programs that equip instructors with robotics teaching competencies are essential for program growth. This investment pays dividends beyond robotics courses themselves. Faculty who develop comfort with robotics technologies often integrate these tools into other courses, enriching the broader curriculum.

Strategic Framework: Building Future-Ready Graduates

Curriculum Design Principles

Effective robotics programs break down traditional departmental silos. Mechanical engineering, electrical engineering, computer science, business, and ethics faculty must collaborate to deliver coherent, integrated curricula.

Industry alignment ensures curriculum relevance. Advisory boards populated with corporate partners provide insight into current and projected workforce needs. These relationships also open doors for student internships, capstone project sponsorships, and equipment donations.

Flexible credentialing expands access. Not every student can or should pursue a full robotics engineering degree. Certificates, minors, and concentrations allow students in other majors to gain robotics competencies. These stackable credentials create multiple pathways into the field.

Infrastructure and Investment

Credible robotics programs require appropriate facilities. State-of-the-art laboratories equipped with current-generation robotics platforms signal institutional commitment and provide students with relevant experience.

Corporate partnerships can offset infrastructure costs. Companies benefit from relationships with universities that produce qualified graduates and conduct relevant research. Equipment donations, sponsored laboratories, and collaborative research agreements create mutual value.

Not every institution can or should build a comprehensive robotics engineering program. Smaller investments can still yield significant returns. Robotics clubs and extracurricular activities introduce students to the field at low cost. Competition teams develop skills while building community. Individual courses embedded within existing majors expose students to robotics concepts without requiring new degree programs.

Experiential Learning Integration

Classroom instruction provides foundations; experiential learning builds professional competence.

Universities should support student participation in robotics competitions. The REC Foundation data confirms that participants are more likely to pursue STEM careers. Integrating internships and cooperative education experiences into degree programs ensures students gain professional experience before graduation.

Capstone projects with real clients offer particularly valuable learning opportunities. Partnerships with local industries provide authentic problems for students to solve, complete with the ambiguity, constraints, and stakeholder complexity that characterize professional practice.

Equity and Access Considerations

Robotics education should not be reserved for students at well-resourced institutions or those who arrive with prior exposure to technology. Universities have both ethical obligations and practical incentives to expand access.

Grant funding can support this expansion. The National Science Foundation's Advanced Technological Education program, state workforce development funds, and private foundations all provide resources for robotics education initiatives.

Community college partnerships create pathways for students who might not otherwise access four-year robotics programs. Articulation agreements that recognize community college coursework allow students to transfer into university programs with advanced standing. These partnerships also strengthen regional workforce ecosystems.

Conclusion: The Imperative for Action

The transformation of the global workforce is not a future possibility. It is a present reality accelerating with each passing year.

Universities that invest in robotics education now will produce graduates who lead in innovation, command premium compensation, and shape the industries of tomorrow. Institutions that delay will produce graduates who struggle to find their footing in an economy that has moved beyond their preparation.

The benefits of action extend beyond student outcomes. Universities that embrace robotics strengthen their competitive positions, attract research funding and corporate partnerships, and fulfill their missions as engines of social mobility and economic development.

Robotics education is not about replacing human capacities. It is about amplifying them. The goal is to produce graduates who can design intelligent systems, collaborate effectively with automated tools, and apply human judgment where it matters most. These graduates will not compete with robots. They will lead the organizations that deploy robots to solve pressing problems.

University leaders should convene institutional stakeholders to assess current capabilities and chart a course toward a robotics-integrated future. The time for deliberation has passed. The time for action is now.

Sources

World Economic Forum. Future of Jobs Report 2025. January 2025.

Grand View Research. Educational Robot Market Size, Share & Trends Analysis Report. 2024.

Robotics Education & Competition Foundation. Official website: recf.org.

International Federation of Robotics. World Robotics Report. 2022.

Humanities and Social Sciences Communications (Nature). "A decade of educational robotics: trends and SDG contributions." August 2025.

Association for Advancing Automation. U.S. National Robotics Strategy. March 2025.

College Survival Guide: What to Do Before You Arrive and Every Year After

College Survival Guide: What to Do Before You Arrive and Every Year After

How to Use Your Cultural Identity to Stand Out in Business Careers

How to Use Your Cultural Identity to Stand Out in Business Careers

AI for Job Seekers: Safe, Smart Tools That Help You Stand Out to Employers

AI for Job Seekers: Safe, Smart Tools That Help You Stand Out to Employers

What Employers and Admissions Officers Look for in International Candidates

What Employers and Admissions Officers Look for in International Candidates

Double Major in College: Smart Strategies That Actually Work

Double Major in College: Smart Strategies That Actually Work